- Features

- Technical Data

For our sublimation heat transfer ink, first print image on sublimation paper, second put the paper on fabric, and then press the paper with transfer machine. Under the temperature about 190°C-220°C, the ink on paper will become gas and go into fabric. So the image will be from paper to fabric.

Advantages of sublimation heat transfer ink:

* Excellent color reproduction, gorgeous color, not color cast. High printing performance. All the colors are very intense.

* No crust in 28-30 days (open the cover),save 20% compared with other ink when printing on machine

* Applicable to synthetic fabrics such as polyester fabric, smooth feel comfortable, no hard feeling.

* Transferred pattern scratch-resistant, washable, non-cracking, no peeling, no fading, and good weather resistance.

* Good stability on the machine, clear dot reproduction, excellent ink-water balance.

Use Scope

Offset (one color, two color and four color machines)

Use Method

(1)Be able to adapt to the demand for middle-speed or high-speed printing.

(2)During the normal condition, use the ink on the machine directly.

Suitable Fabrics

Polyester fabric, Triacetate fabric, Nylon fabric,Acrylic fabric, Polypropylene nitrile.

Transfer Paper

Coated paper, offset paper,chrome paper and calendered paper.

Transfer paper should be 80-90 gr/m2 with dimensional stability.

Packing

1kg/tin or 2kg/tin;12kg/carton

Transfer process:

(1) Print the image on paper, and normal paper is ok.

(2)Put the printed paper on substrate, such as polyester and nylon fabric.

(3)Put the paper and fabric on the heat-transfer machine. When the temperature reaches 180-220°C, the image will betransfer printed from paper onto the substrate.

The following is the transfer printing parameters for your reference

| Name of fabric | Transfer temperature | pressure | Time |

| Polyester fabric | 205°C~220°C | 0.5kg/cm2 | 10~30 seconds |

| Polyester deformation fabric low elastic | 195°C~205°C | 0.5kg/cm2 | 30 seconds |

| Triacetate fabrics | 190°C~200°C | 0.5kg/cm2 | 30~40 seconds |

| Nylon fabric | 195°C~205°C | 0.5kg/cm2 | 30~40 seconds |

| Acrylic fabric | 200°C~210°C | 0.5kg/cm2 | 30 seconds |

| Two acetate fiber fabric | 185°C | 0.5kg/cm2 | 15~20 seconds |

| Polypropylene nitrile | 190°C~220°C | 0.5kg/cm2 |

10~15 seconds |

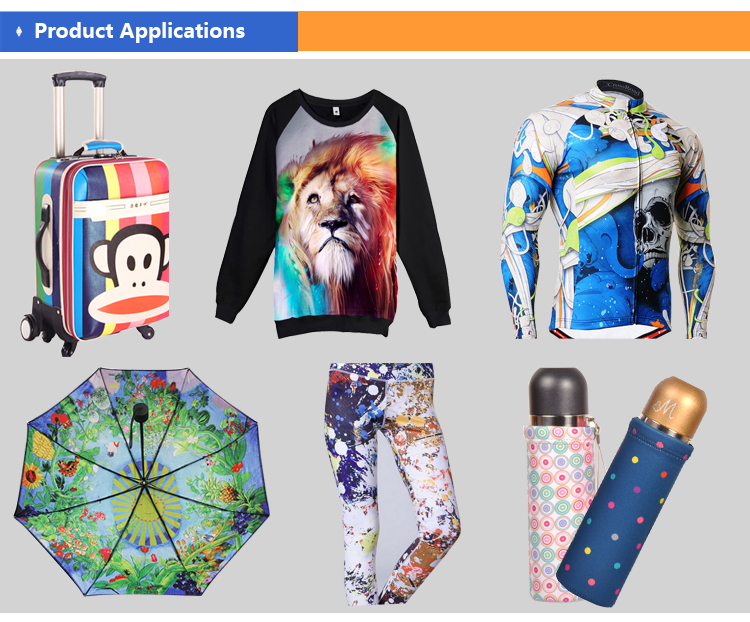

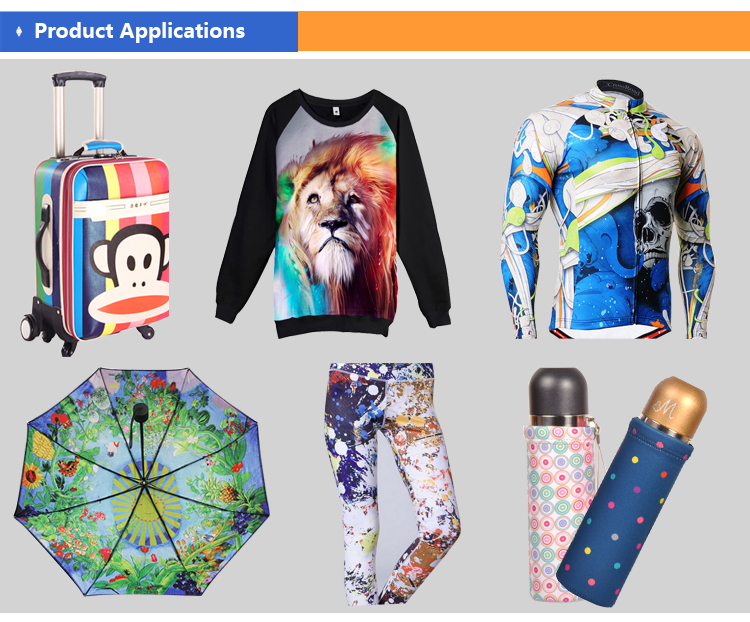

Product application:

Company Information

1. We are the largest chinese manufacturer of sublimation inks

2. We are the dierect manufacturer,have more than 15 years history

ZHONGLIQI

Henan Zhongliqi Printing Material Co., Ltd

Sales Manager: Amy Xu

Skype: zhluqi1234

QQ: 2321938028

Mobile/WhatsApp/Wechat:+8615083132882

Fore more details, contact us pls.

For our sublimation heat transfer ink, first print image on sublimation paper, second put the paper on fabric, and then press the paper with transfer machine. Under the temperature about 190°C-220°C, the ink on paper will become gas and go into fabric. So the image will be from paper to fabric.

Advantages of sublimation heat transfer ink:

* Excellent color reproduction, gorgeous color, not color cast. High printing performance. All the colors are very intense.

* No crust in 28-30 days (open the cover),save 20% compared with other ink when printing on machine

* Applicable to synthetic fabrics such as polyester fabric, smooth feel comfortable, no hard feeling.

* Transferred pattern scratch-resistant, washable, non-cracking, no peeling, no fading, and good weather resistance.

* Good stability on the machine, clear dot reproduction, excellent ink-water balance.

Use Scope

Offset (one color, two color and four color machines)

Use Method

(1)Be able to adapt to the demand for middle-speed or high-speed printing.

(2)During the normal condition, use the ink on the machine directly.

Suitable Fabrics

Polyester fabric, Triacetate fabric, Nylon fabric,Acrylic fabric, Polypropylene nitrile.

Transfer Paper

Coated paper, offset paper,chrome paper and calendered paper.

Transfer paper should be 80-90 gr/m2 with dimensional stability.

Packing

1kg/tin or 2kg/tin;12kg/carton

Transfer process:

(1) Print the image on paper, and normal paper is ok.

(2)Put the printed paper on substrate, such as polyester and nylon fabric.

(3)Put the paper and fabric on the heat-transfer machine. When the temperature reaches 180-220°C, the image will betransfer printed from paper onto the substrate.

The following is the transfer printing parameters for your reference

| Name of fabric | Transfer temperature | pressure | Time |

| Polyester fabric | 205°C~220°C | 0.5kg/cm2 | 10~30 seconds |

| Polyester deformation fabric low elastic | 195°C~205°C | 0.5kg/cm2 | 30 seconds |

| Triacetate fabrics | 190°C~200°C | 0.5kg/cm2 | 30~40 seconds |

| Nylon fabric | 195°C~205°C | 0.5kg/cm2 | 30~40 seconds |

| Acrylic fabric | 200°C~210°C | 0.5kg/cm2 | 30 seconds |

| Two acetate fiber fabric | 185°C | 0.5kg/cm2 | 15~20 seconds |

| Polypropylene nitrile | 190°C~220°C | 0.5kg/cm2 |

10~15 seconds |

Product application:

Company Information

1. We are the largest chinese manufacturer of sublimation inks

2. We are the dierect manufacturer,have more than 15 years history

ZHONGLIQI

Henan Zhongliqi Printing Material Co., Ltd

Sales Manager: Amy Xu

Skype: zhluqi1234

QQ: 2321938028

Mobile/WhatsApp/Wechat:+8615083132882

Fore more details, contact us pls.

- Leave A Message

Note: If you're interested in the product, please submit your requirements and contacts and then we will contact you in two days. We promise that all your informations won't be leaked to anyone.